2022年2月28日 In-Pit Crusher Conveyor (IPCC) systems offer advantages in the form of continuous operation, reduced labour requirements and decreased energy consumption

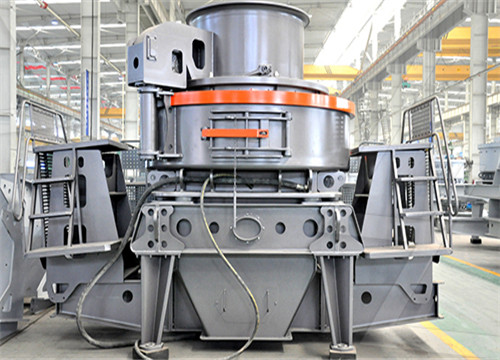

IPCC represents a viable, safer and less fossil fuel dependent alternative. A typical IPCC system comprises fully-mobile, semi-mobile or fixed in pit crushing stations connected to

Abstract: The COAL CRUSHING AND CONVEYER SYSTEM will include the design and construction of a microcontroller based coal crushing and conveyer system with DTMF

One of the most challenging aspects in semi-mobile in-pit crushing and conveying (SMIPCC) system design is determining the optimum depth at which to change from a purely truck

One of the most challenging aspects in semi-mobile in-pit crushing and conveying (SMIPCC) system design is determining the optimum depth at which to change from a purely truck

conveying systems are frequently with fixed crusher installations, more mobile systems have found limited application in large hard rock open pits, and a greater emphasis is put on

Belt Speed. 1.25 2.0 m/s. Nesans Crusher Plant Belt Conveyor Systems come with Supreme quality combined with reliable engineering. With More than 500 Km of total

2011年10月24日 One of the newest innovative technology that is developed by MMD supplier (Mining Machinery Developments) in 2019, is using continuous mining and existing truck fleet together without the

2021年1月10日 Regarded as the lifelines of any crushing operation, conveyor systems are some of the most valuable machines on the job site as they are designed to quickly

Creating a drive system for multiple conveyor belts requires in-depth know how. Our offering, based on our experience applying solutions on more than 600 kilometers of belt conveyors, uses modern simulation techniques,

2022年2月28日 In-Pit Crusher Conveyor (IPCC) systems offer advantages in the form of continuous operation, reduced labour requirements and decreased energy consumption resulting in lower cost per bank cubic metre. Nevertheless, IPCC systems are associated with high capital costs, lack of flexibility to adapt to changing mine plans and low effective

IPCC represents a viable, safer and less fossil fuel dependent alternative. A typical IPCC system comprises fully-mobile, semi-mobile or fixed in pit crushing stations connected to a network of conveyors and spreaders (for waste) or stackers (for ore) to efficiently transport material out of a mine. Besides the significant potential to reduce

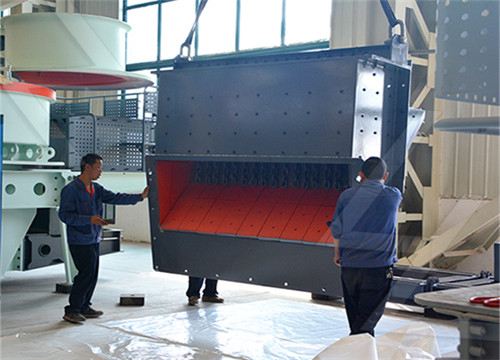

2016年2月24日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of parties.

2011年1月1日 Jan 2003 D L Schroder Schroder, D.L., 2003, The use of in-pit crushing and conveying methods to significantly reduce transportation costs by truck, Coaltrans Asia, Bali International Convention...

Integrated continuous mining techniques such as fully mobile in-pit crusher and conveyor (FMIPCC) systems offer inherent labour, energy and environmental benefits to deep pit metalliferous...

2016年4月8日 The conveyor belt is one of the widely used, interconnected transportation system in the today industry. Conveyor belt, which is a permanent means of transportation, has higher power and cargo transportation ability than the volume it needs.

2021年1月10日 Regarded as the lifelines of any crushing operation, conveyor systems are some of the most valuable machines on the job site as they are designed to quickly transport bulk product from one point to another in order to greatly reduce the time spent manually handling the product.

There are three different types of conveyor belts: the basic belt, snake sandwich belt and long belt. ? main components of in pit crusher and conveyor belts Continental belt conveyor components move more of replacement components for equipment used in open pit mining and equipment crusher

Mining Systems and Equipment TAKRAF is recognized as one of the world's leading technology brands providing specialized mining systems and equipment.Owners and operators around the world trust our engineered solutions that leverage our experience acquired over more than a century. Our portfolio ranges from excavating to primary

Crushing and conveying Belt conveyor systems Mining belt conveyor systems Increasing efficiency and extending conveyor belt life cycle Creating a drive system for multiple conveyor belts requires in-depth

2022年2月28日 In-Pit Crusher Conveyor (IPCC) systems offer advantages in the form of continuous operation, reduced labour requirements and decreased energy consumption resulting in lower cost per bank cubic metre. Nevertheless, IPCC systems are associated with high capital costs, lack of flexibility to adapt to changing mine plans and low effective

IPCC represents a viable, safer and less fossil fuel dependent alternative. A typical IPCC system comprises fully-mobile, semi-mobile or fixed in pit crushing stations connected to a network of conveyors and spreaders (for waste) or stackers (for ore) to efficiently transport material out of a mine. Besides the significant potential to reduce

Belt conveyor systems continuously transport all forms of material, including excavated and crushed rock, in an efficient manner due to their 100% effective availability. They cover a wide range of applications, from mining or extraction to in-plant or overland where they convey material over long distances, passing through curves and rough

2011年1月1日 Jan 2003 D L Schroder Schroder, D.L., 2003, The use of in-pit crushing and conveying methods to significantly reduce transportation costs by truck, Coaltrans Asia, Bali International Convention...

Integrated continuous mining techniques such as fully mobile in-pit crusher and conveyor (FMIPCC) systems offer inherent labour, energy and environmental benefits to deep pit metalliferous...

2021年1月10日 Regarded as the lifelines of any crushing operation, conveyor systems are some of the most valuable machines on the job site as they are designed to quickly transport bulk product from one point to another in order to greatly reduce the time spent manually handling the product.

There are three different types of conveyor belts: the basic belt, snake sandwich belt and long belt. ? main components of in pit crusher and conveyor belts Continental belt conveyor components move more of replacement components for equipment used in open pit mining and equipment crusher

Conveyor Industries Conveying SystemsEquipment. Air Supported Belt Conveyors; Belt dedicated to the production of reliable customised conveyors and screw conveying systems

2019年2月7日 Staneco Corporation designed a crusher conveyor control system to replace an existing relay panel. The system consisted of conveying material through a series of conveyors and hydraulic crushers. Crushed material was then conveyed and separated by size and conveyed to different piles.

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين