2016年1月1日 Micro-grinding is one such process that has been proved optimal thanks to its ability to produce micro-features with higher surface finish. In this study, we review the basic mechanism of micro-grinding, the development of micro-grinding tools, micro

2010年1月1日 The ultra-precision grinding process is characterized by material removal with depths of cut in the sub-micrometer range often in ductile mode, low feed and

2019年5月18日 Micro-grinding is a tool based mechanical micromachining process which is mostly applied to create and finish 3D micro-features on hard and brittle materials such

2019年10月1日 Therefore, it is necessary to investigate the influence of microstructure on the material removal mechanism of AlON under ultra-precision grinding. In this , an

2017年11月22日 Abstract Ultra-precision micro machine tool (UPMMT) has always been a high-precision machine tool for microscale/

2010年1月1日 This keynote stone introduces general aspects of ultra-precision grinding techniques and point out the essential features of ultra-precision grinding. In particular,

Grinding high-precision parts made of hard and brittle materials. High-precision parts made of hard and brittle materials such as tungsten carbide, ceramics or glass, are used in a

2017年6月19日 The conception, applications and history of ultra-precision machining are introduced in this article, and the developments of ultra-precision machining

2019年2月8日 1 Introduction Manufacturing technologies offer plenty of opportunities to improve sustainability by reducing environmental impact or by the more efficient use of

2023年5月4日 At the feed rate of 10 mm/min, the average surface roughness was reduced from 132.5 nm to 40.6 nm after one pass of polishing (~9.3 min of polishing time).

2019年7月1日 In mechanical machining, ultra-precision machining is a very-promising method, providing high efficiency, high flexibility, and low cost for creating the high quality surfaces with achievable sub-micrometric form accuracy and nanometric surface roughness [2, [4], [5], [6], [7]].

2012年8月28日 Paul Shore and Paul Morantz Published: 28 August 2012 https://doi/10.1098/rsta.2011.0638 Abstract This stone provides a perspective on the development of ultra-precision technologies: What

2020年9月3日 The recent stone proposes a hybrid micro-grinding process for ultra-precision meso/micro components of monocrystalline silicon manufacturing. The proposed technique utilizes the chemical modificati...

2021年9月8日 The non-contact nature of electrical discharge machining (EDM) process makes it more competent in fabricating micro tools with relatively high efficiency and low cost; especially the wire electrical discharge grinding (WEDG) invented in 1985 provides a new approach and direction to fabricate micro tools; following this trend, numerous new

Ultra-precision grinding Grinding high-precision parts made of hard and brittle materials High-precision parts made of hard and brittle materials such as tungsten carbide, ceramics or glass, are used in a range of sectors including tool and die making industry, the optical industry or in medical technology applications.

2019年2月8日 1 Introduction Manufacturing technologies offer plenty of opportunities to improve sustainability by reducing environmental impact or by the more efficient use of resources. Possible improvements in sustainability

2014年1月1日 Herein the term micromachining refers to mechanical micro cutting techniques where material is removed by geometrically determined cutting edges. The aim of this review article is to summarize...

2021年5月7日 Foreword. The CHINA-JAPAN International Conference on Ultra-Precision Machining Process (CJUMP) was initiated in 1984. The CJUMP2021 will be held in Jinan City, China, during November 19-21, 2021. The goal of the conference is to bring together researchers and academics from China and Japan to discuss novel theories,

2023年2月22日 A new micro-grinding process called ultrasonic vibration-assisted nanoparticle jet mist cooling (U-NJMC) is innovatively proposed to solve the technical problem. It combines the advantages of ultrasonic vibration (UV) and nanoparticle jet mist cooling (NJMC).

2023年5月4日 At the feed rate of 10 mm/min, the average surface roughness was reduced from 132.5 nm to 40.6 nm after one pass of polishing (~9.3 min of polishing time). Selected SEM photos of the polished surface at different feed rates are also shown in Fig. 9 in order to compare the surface quality after polishing.

2020年9月3日 The recent stone proposes a hybrid micro-grinding process for ultra-precision meso/micro components of monocrystalline silicon manufacturing. The proposed technique utilizes the chemical modification solution to modify and soften the surface layer and then manufactures meso/micro-structures via micro-grinding.

Ultra-precision grinding Grinding high-precision parts made of hard and brittle materials High-precision parts made of hard and brittle materials such as tungsten carbide, ceramics or glass, are used in a range of sectors including tool and die making industry, the optical industry or in medical technology applications.

2021年4月1日 Therefore, the main material removal mechanism of ultra-fine diamond powder in ultra-precision grinding is micro cutting, which produces plastic deformation, makes the contour peak gentle and smooth, and reduces the surface roughness value.

2018年12月31日 Ultra-precision grinding of hard and brittle materials such as optical glass, ceramics, cemented carbides, and crystal materials has been applied in a wide range of applications in order to obtain high-quality surfaces with nanoscale roughness, submicron form accuracy, and micron-level subsurface damage.

2021年5月7日 In order to adapt the new situation of ultra-precision machining and surface finishing technology, this conference will cover new developments for process technology on machine tool,...

2023年5月4日 Several methods have been developed to generate structured surfaces, including milling [ 6 ], turning [ 7 ], grinding [ 8 ], chiseling [ 9 ], electrical discharge machining [ 10 ], laser machining [ 11 ], abrasive jet machining [ 12 ], etc.

1 Micromachining is a process that uses high-speed, high-precision micro tools with geometrically defined cutting edges to make devices or features with at least some of their dimensions in the micrometer range.

2014年4月23日 micro parts as well as precision structured surfaces. In this field mechanical machining processes, like diamond machining, play a dominant role. Novel mechanical manufacturing processes, further development of ultra precision machine tools and the precision machining of challenging materials yield a great potential as enabling

Global Supplier of Ultra-Precision Machining Systems. Single Point Diamond Turning. Micro-Grinding. Micro-Milling. Glass Press Molding. REQUEST A QUOTE. Global Supplier of Ultra-Precision Machining Systems. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or

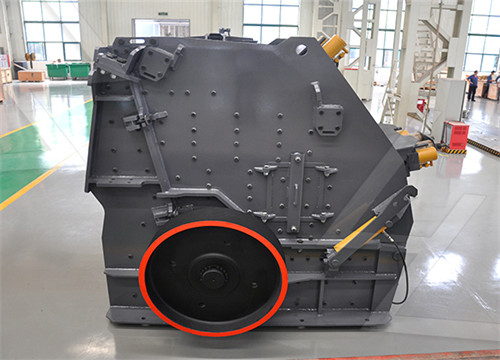

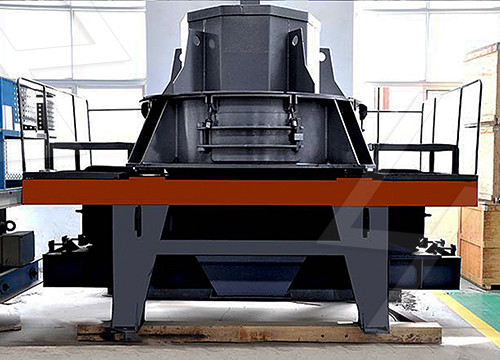

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين