+10% crusher throughput and +23% crusher availability. Reduce downtime 69% reduction in primary crushing downtime. Improve quality 70% increase in the required feed for grinding with optimized crusher liners. Reliable, energy efficient crushing solutions for mining

2018年4月24日 Some important types of availability are discussed .For the analysis; crusher machine is considered, to evaluate the availability of crusher machine, the

2022年3月7日 availability are discussed .For the analysis; crusher machine is considered, to evaluate the availability of crusher machine, the availability of each essential

2016年2月24日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production

2023年2月7日 The plant availability is the actual level of availability realized in day to day operation of the crushing plant. Plant availability is related to preventive maintenance and

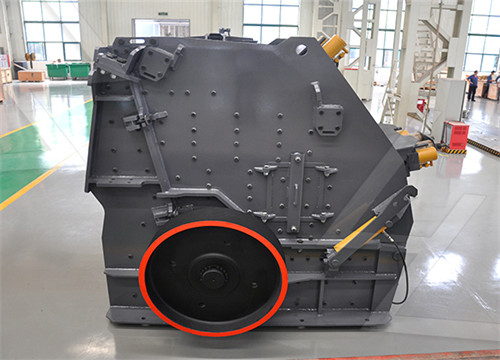

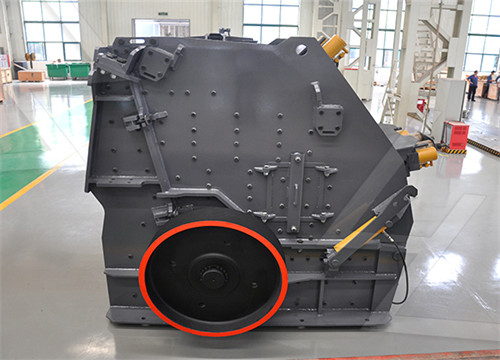

The impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance. The finished product is of cube shape and the tension force

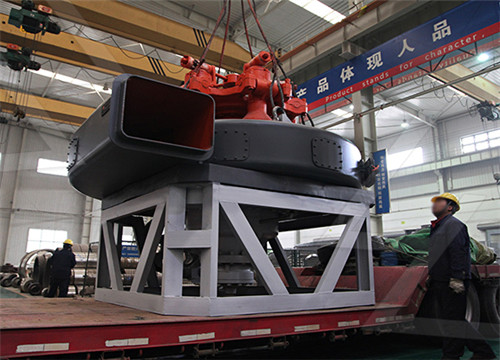

2021年8月15日 This work opens with a brief review of the mechanical principles of cone crushers. Then, in the following sections, works available in the cone crusher literature,

Equipment Types of Crushers: What You Need to Know Types of Crushers: What You Need to Know What is a crusher? Before we discover all the different types of crushers we

2002年10月1日 A performance model for impact crushers October 2002 DOI: 10.1016/S0892-6875 (02)00174-7 Authors: Svetoslav Nikolov Bulgarian Academy of Sciences Abstract and Figures In this stone we

2021年11月6日 The stone concerns investigation of the effect of impact crusher operation on selected qualitative characteristics of mineral aggregate products. Qualitative

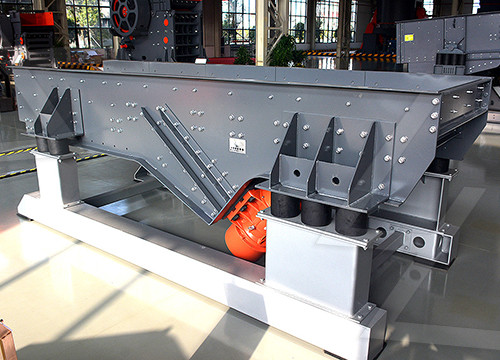

A continuous equipment development programme ensures minimum wear, maximum availability, very low maintenance requirements and extreme flexibility regarding establishment of machine and product parameters. The compound crusher was developed to avoid the problems and the investment of a closed-circuit operation. The

2016年2月24日 INTRODUCTION The fundamental goal for the design of a crushing plant is an installation that meets the required production requirements, operates at competitive cost, complies with today’s tough environmental regulations, and can be built at a reasonable price despite the rising costs of equipment, energy and construction labor.

Global Crusher Machine Market by Type (Jaw Crusher, Gyratory Crusher, Cone Crusher), By Application (Mining, Construction, Industry, Others) And By Region (North America, Latin America, Europe, Asia Pacific and Middle EastAfrica), Forecast From 2022 To 2030. Report ID: 216576 4200 MachineryEquipment Dataintelo 151 Pages 4.9 (38) Report

2019年6月28日 Crushers play an important role in the material handling process for underground mine operations. The main purpose of a crusher is the size reduction of the feed. This size reduction is achieved by applying

2021年8月15日 The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher. The CSS is easily changed online in a large variety of commercial crushers; different principles of CSS adjustment are described in (Quist, 2017).The maximum distance between the mantle and concave, on the other

2009年6月1日 The measured crusher throughput during the validation test was 40.7 kg/min, and the result from the simulation was 41.5 kg/min. Agreement was therefore excellent. Fig. 2 shows the comparison between the measured and simulated product size distributions.. Download : Download full-size image Fig. 2.. Simulated and experimental

Equipment Types of Crushers: What You Need to Know Types of Crushers: What You Need to Know What is a crusher? Before we discover all the different types of crushers we need to know what a crusher is and what it is used for. A crusher is a machine that reduces large rocks into smaller rocks, gravel, or rock dust.

2017年6月30日 increased the availability of a jaw crusher by 17%, reduced breakdown and mean time to repair by 89%, while the maintenanc e was reduced by 86%.

2016年1月26日 This EXAMPLE Small Crushing Plant is designed to crush 500 tonnes per day, operating 12 hours per day with an availability of 70%. The Plant will crush run-of-mine material (-16″) to 100%, passing 5/8″ at

2020年5月5日 A can crusher machine is used to crush the cans for storing in bin efficiently. The crushing of cans plays a significant role in economy and ultimately helps to society. The process of cans...

Our impact crushers Impactors: The heart of stationary, semi-mobile and mobile crushing plants. Learn more about our Impact Crushers...

Offering Crushers are machines used to reduce the size of rocks, stones and ore. They are often utilized in aggregates production, construction material recycling and in mining operations. Metso offering covers different gyratory crushers, jaw crushers, cone crushers and impact crushers optimized for any size reduction need.

Global Crusher Machine Market by Type (Jaw Crusher, Gyratory Crusher, Cone Crusher), By Application (Mining, Construction, Industry, Others) And By Region (North America, Latin America, Europe, Asia Pacific and Middle EastAfrica), Forecast From 2022 To 2030. Report ID: 216576 4200 MachineryEquipment Dataintelo 151 Pages 4.9 (38) Report

2019年6月28日 1 Introduction 2 Location of the Crusher In an Underground Mine 2.1 Near the Shaft 2.2 Under the Orebody 3 Material Handling 3.1 Pre-Crushing 3.2 Crushing 3.3 Post Crushing 4 Technology

2009年6月1日 1. Crusher design evolution Compression cone crusher designs today have evolved from the simple cone crusher first developed in the mid-1920s by Edgar B. Symons, to the modern high performance crushers. Early crushers used springs for tramp iron protection and were manually adjusted.

Crushing and Screening Handbook. Kevin Berrocal. We have the expertise to build a fl eet of track mounted crushing and screening plants for primary, secondary and tertiary stages according to your application. Moving

2020年5月5日 A can crusher machine is used to crush the cans for storing in bin efficiently. The crushing of cans plays a significant role in economy and ultimately helps to society. The process of cans...

2023年6月12日 Propel manufactures stationary, skid mounted and semi mobile plants between the capacities range of 150 600 TPH. Propel crusher equipment are available between 150-200-400 TPH ranges.

With 85% efficiency the hourly productivity of a single crusher is 50, 16, 16 cubic meters of 02, 01, and 00 aggregates 4. Cost 4.1. Production cost Production cost is not available for outside visitors unless a formal and legally written letter is submitted. 4.2.

2021年11月21日 The formula for calculating capacity of jaw crusher: C JC = G.W / CSS Where: C JC = Capacity of Jaw Crushers G = Gape Size W = Width of Crusher CSS = Closed Single Setting of Jaw Crushers Let’s solve an example; Find the capacity of jaw crusher when the gape size is 10, the width of crusher is 8 and the closed single setting

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين