Our roller mills consistently and safely grind wheat, corn, rye, barley, spelt and other grains. We offer a wide range of roller mills and optional functions to match the milling solutions

OverviewWorking principleTypesGristmill conversionOther applicationsHistorySee also

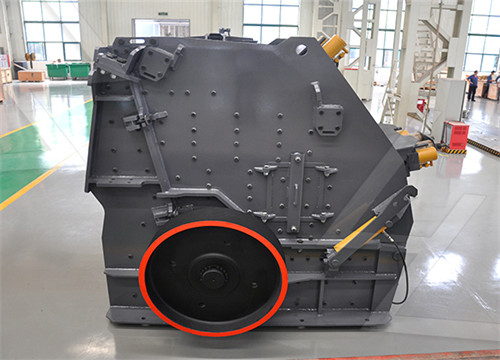

A motor or other prime mover drives the hanger of the grinding roller to rotate through a V pulley and center bearing. The roller, which is hung by a bearing and pendulum shaft, will roll along the inner circle of the roll ring while the hanger is rotating. A dust removal blower will generate negative pressure at the inlet and outlet of the grinder to prevent dust and radiating the heat in the machine.

Simultaneous Grinding and Drying. Williams roller mills can perform simultaneous grinding and drying functions with one continuous operation. The roller mills simultaneous grinding and drying features are typically

The roller mill’s ability to reduce materials to a uniform particle size provides more control of product characteristics and minimizes waste, as shown in Figure 1. The mill’s controlled

Find your roller mill easily amongst the 200 products from the leading brands (Brabender, WAMGROUP, Metso,) on DirectIndustry, the industry specialist for your professional purchases.

Find your roller mill easily amongst the 82 products from the leading brands ( Group,) on AgriExpo, the agricultural machinery and equipment specialist for your

2009年1月1日Abstract. Based on screening analysis, laser size analysis, grindability and rigidity tests of samples collected on line from a cement and a power plant, a simulation

Raymond roller grinding mill is mainly applicable to the grinding and processing of mineral product materials such as metallurgy, building materials, chemicals, and mines. Raymond mill can process various

Ring Roller Grinding Mill. Table of Contents [ hide] 1 Brief Introduction. 1.1 HGM Series Micro Powder Grinding Mill. 1.2 YGM Series High Pressure Suspension Grinding Mill.

Vertical roller mills offer supreme grinding with high energy-efficiency Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs.

Roller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and others. Roller grain mills are an alternative to traditional millstone arrangements in gristmills.

Williams has been the industry leader for crushing and pulverizing machines since 1871. All of our machines are innovative and designed to be rugged and dependable. Our team sets itself apart with a diverse product line

Daniel Ephraim Modern Process Equipment This article introduces roller mills and explains howthey efficiently grind friable materials to a uniformfinal particle size while using relatively little energyand minimizing waste.

2019年2月21日The mill is equipped with a hopper and a grinding product basket. The gaps between the rotating rollers and the friction plate are adjustable, depending on the nature of batch and requirements of the grinding

2017年9月11日In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg. Samples were collected from mill inside and around the circuit to evaluate the

2016年10月5日In this chapter an introduction of widely applied energy-efficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over

2015年3月10日The Institute of Mineral Processing at the Montanuniversitaet Leoben in cooperation with the company CEMTEC has developed a pilot scale, 200 mm table diameter, vertical roller mill for energy controlled laboratory tests.The mill provides the technical options to vary process parameters like air-flow, mass flow, grinding force and

2022年1月23日This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters. For design of experiments (DOE), the response surface method (RSM) was employed with the VRM experiments to systematically investigate the influence of operating parameters on

Efficient Compared with jet mill, mixing grinder and ball mill of same finished product size and motor power, MW Micro-Powder Mill has double capacity and saves 30% energy. 2. Long Life of Spare Parts Forged by special material, the ring and roller can be used for about one year while grinding calcium carbonate.

Vertical roller mills offer supreme grinding with high energy-efficiency Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs.

Williams has been the industry leader for crushing and pulverizing machines since 1871. All of our machines are innovative and designed to be rugged and dependable. Our team sets itself apart with a diverse product line

2019年2月21日The mill is equipped with a hopper and a grinding product basket. The gaps between the rotating rollers and the friction plate are adjustable, depending on the nature of batch and requirements of the grinding

The roller mill, when equipped with a variable speed mill drive, can be used in applications requiring adjustable Raymond roller mills are available with grinding ring diameters ranging from 30 inches to 120 inches (760 to 3050 mm). These sizes are capable of producing a wide range of product fineness from a wide variety of material.

2017年9月11日In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg. Samples were collected from mill inside and around the circuit to evaluate the

Then adopting center chute mill allows long stable mill operation. For avoiding metallic contact between roller tire and table liner UBE mill equips MECHANICAL STOPPER. Furthermore, coil spring is equipped in

2016年10月5日In this chapter an introduction of widely applied energy-efficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over

2022年1月23日This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters. For design of experiments (DOE), the response surface method (RSM) was employed with the VRM experiments to systematically investigate the influence of operating parameters on

Product Feature. Particle Size Quite different from Raymond mill which can produce particles coarser than 400 mesh only, roller mill can produce particles in the range from 325 mesh to 2500 mesh at one time. Its products range from coarse powder to ultra-fine powder, and the fineness of its end product can reach D97 ≤3μm.

double-roller mill R series. horizontal almond robust. Motor power: 1, 3 kW. Machine length: 810, 1,290 mm. Machine width: 630, 940 mm. Two cylinder refiner The two cylinder grinder is a strong, solid machine of simple use. The utilization of special materials for the construction of the support and transmission organs as well as a few

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين