2004年6月25日 Our final goal is to determine the optimum condition in wet milling and to establish the rule for scaling up of a mill under wet condition; but in this , we would

The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8 kg. It allows for

2001年1月15日 Kinetics of fine wet grinding in a laboratory ball mill MYekelera AOzkana L.GAustinb Add to Mendeley https://doi/10.1016/S0032-5910 (00)00326-0 Get rights

2021年8月12日 The operation of a planetary ball mill under wet or dry state is another decisive factor that must be considered to make the grinding process successful.

2004年6月25日 A method for simulating the motion of balls in tumbling ball mill under wet condition is investigated. The simulation method is based on the three-dimensional

case the kinetic energy is rstly transferred to the mill body and then to the grinding medium. These ball mills are the most widely used in the eld of cellulose and they can be further

2001年1月15日 Experience has shown that the best grinding conditions in ball mills are produced by a slurry density which makes grinding more efficient than dry grinding [4]. In

1 DOVE Ball Mills are used in supplied and applicable for wet and dry grinding applications within the following branches of industries: Mining, Hard Rock (primary

2021年11月29日 The grinding methods of ball mills can be divided into two types: dry grinding and wet grinding. Wet grinding has a wide range of applications. Wet grinding

2017年7月3日 Wet grinding gave 39 percent, more capacity and 26 percent more efficiency than dry grinding. These values supplement those shown in table 16. Type of Grind with Different Amounts of Ore Charges

The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8 kg. It allows for grinding up to 220 ml sample material per batch.

2001年1月15日 Kinetics of fine wet grinding in a laboratory ball mill MYekelera AOzkana L.GAustinb Add to Mendeley https://doi/10.1016/S0032-5910 (00)00326-0 Get rights and content Abstract S Keywords 1. Introduction It is well known that it is very difficult to reach ultrafine sizes by dry grinding in a tumbling ball mill.

行星式球磨仪 PM 400. The PM 400 is a robust floor model with 4 grinding stations and accepts grinding jars with a nominal volume from 12 ml to 500 ml. It processes up to 8 samples simultaneously which results in a high

2016年9月1日 The investigation was limited to wet grinding overflow discharge ball mills, as the majority of operational ball mills are of this type. In a grinding mill, particles require sufficient time to be ground in order to achieve the desired size reduction. If the mill is operated with an excessively high feed rate, particles would be ‘washed out

2012年6月1日 Grinding in Ball Mills: Modeling and Process Control Cybernetics and Information Technologies DOI: 10.2478/cait-2012-0012 Authors: Vladimir Monov Bulgarian Academy of Sciences Blagoy Sokolov...

Ball milling is a simple, fast, cost-effective green technology with enormous potential. One of the most interesting applications of this technology in the field of cellulose is the preparation and the chemical modification of cellulose nanocrystals and nanofibers.

1 NETZSCH is one of the market leader in wet grinding technology. The bundling of process-related know-how and the extensive machine program from laboratory to production machines to complete production lines is our strength. Agitator bead mills are grinding machines for ultra-fine processing of solids in liquids.

2020年11月13日 Back 1) Wet grinding Wet grinding means that the material is ground with water (or absolute ethanol) in the ball mill, and when the grinding particle size meets the requirements, the material will be taken out by the water flow. 2) Dry grinding

2015年9月2日 ball mill by grinding the raw bauxite and converting it to required fined grade. Calcined bauxite is used to make refractory bricks, abrasives and for steel polishing. Here I have discussed some issues with the ball mill grinding process like moisture content, its drawbacks on efficiency and how to remove this moisture content from the process

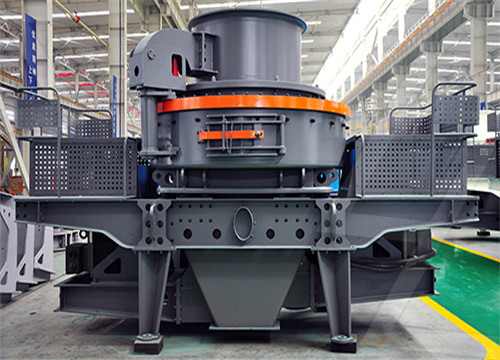

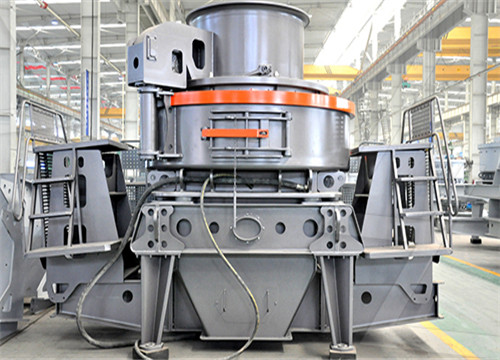

Wet ball mill is applied for the wet grinding work . It could applied for the mining and mieral processing industry, ceramic industry, glass industry and pigment industry, etc. The working manner could be continuous or batch. ZJH minerals could design and produce all kinds of wet grinding ball mills with different diameter and length.

行星式球磨仪 PM 400. The PM 400 is a robust floor model with 4 grinding stations and accepts grinding jars with a nominal volume from 12 ml to 500 ml. It processes up to 8 samples simultaneously which results in a high

The MM 500 control is a high energy laboratory ball mill that can be used for dry, wet and cryogenic grinding with a frequency of up to 30 Hz. It is the first mixer mill in the market that allows to monitor and control the

Ball mill is typically used to grind and/or blend materials and it can be done wet or dry. It can be used to mix ceramic powders, disperse particles in solvents, homogenize ceramic slurries, etc. Ball mills operate by rotating plastic jars around a horizontal axis, partially filled with the material to be ground plus the grinding medium.

1 NETZSCH is one of the market leader in wet grinding technology. The bundling of process-related know-how and the extensive machine program from laboratory to production machines to complete production lines is our strength. Agitator bead mills are grinding machines for ultra-fine processing of solids in liquids.

Manufacturer of Continuous Feed Ball Mills for WetDry Grinding Applications. Founded in 1984 with the acquisition of the EIMCO ball, pebble and rod mill product lines. Neumann Machinery Company (NMC) is headquartered in West Jordan, Utah, in the USA just 14 miles south of Salt Lake City. The area is steeped in a rich history in the supply of

2017年7月3日 Wet grinding gave 39 percent, more capacity and 26 percent more efficiency than dry grinding. These values supplement those shown in table 16. Type of Grind with Different Amounts of Ore Charges

2014年11月13日 wet grinding 4 general description Embed Size (px) <iframe src="https://vdocuments.net/embed/v1/ball-mill-558451ec9eaf0" frameborder="0" marginwidth="0" marginheight="0" scrolling="no" style="border:1px solid #CCC; margin-bottom:5px; max-width: 100%; overflow: hidden; width: 599px; height: 487px;"

2015年9月2日 INTRODUCTION This stone is based on the producing calcined bauxite with the help of ball mill. Calcined Bauxite is obtained by calcining (heating) superior grade Bauxite at high temperature (from 850 °C to 1600 °C). This removes moisture thereby increasing the alumina content.

Wet ball mill is a kind of equipment which uses grinding medium and a certain amount of liquid (water or anhydrous ethanol) to grind materials. Unlike dry ball mill, wet ball mill adopts the wet grinding method. The characteristic of wet grinding is that the material needs to be soaked in the liquid for grinding.

Wet ball mill is applied for the wet grinding work . It could applied for the mining and mieral processing industry, ceramic industry, glass industry and pigment industry, etc. The working manner could be continuous or batch. ZJH minerals could design and produce all kinds of wet grinding ball mills with different diameter and length.

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين