2017年5月1日 This study has attempted to develop a fundamental model including performance aspects of the jaw crusher for both potential future adoption in simulations

Jaw crusher: The material is crushed between a fixed jaw and a mobile jaw. The feed is subjected to repeated pressure as it passes downwards and is progressively reduced in

2016年6月1日 To reduce the development cycle and improve the design quality of jaw crusher, this stone takes full advantage of the Function module of the Pro/Engineer

tempts to de-scale jaw-crushers and other size reduction equipment to match budgets of small-scale miners or road contractors using labor based technologies. The New Dawn

A small-scale mobile jaw-crusher unit with a throughput of 1-1.5 tons of aggregates per hour has been designed, manufactured and tested at the Department of Chemical and

2009年10月1日 The present research work deals with the kinematic analysis of the swing jaw plate of a single toggle jaw crusher. Findings During the analysis, the system is

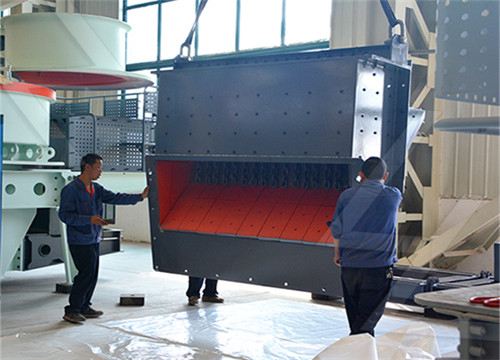

Jaw Crushers. Jaw Crushers are a compression-type machine that crush material between a moving piece of steel and a stationary piece of steel. They are used for primary and

产品细节 背景信息 Details on the fields of application, working mechanisms and materials used in jaw crushers. 更多信息 Standard Unit 颚式粉碎仪 BB 100 最大进样尺寸: < 50

Simplification of Jaw crusher for Artisanal Academic Journals. EN. English Deutsch Français Español Português Italiano Român Nederlands Latina Dansk Svenska Norsk

2022年6月23日 Jaw crusher can reach the crushing ratio of 4-6 and the shape of final product is even. It is widely applied to crush high hardness, mid hardness and soft rocks

2022年9月20日 The plate dimensions of the un-optimised jaw crusher were modelled using ANSYS Design Modeller 2021, as shown in Fig. 3.The load and boundary conditions for the static structural analysis were as shown in Fig. 4.Design of Experiments (DoE) was then conducted where the minimum and maximum values of the target parameters were

2022年11月24日 1. Introduction Jaw crushers are utilized extensively in the industries of mining, metallurgy, building materials, ceramics, and engineering of massive minerals with small and medium particle size crushing [ 1, 2, 3 ].

2017年6月30日 Moreover, the wear of the jaw liner profile lowers the crusher performance by affecting the shape and the overall size of the crushed particles [12, 13]. Warping and wear of the jaw plate cause a

Theoretical, empirical and semi- empirical methods of capacity determination of a single-toggle jaw crusher are given, taking into account physico-mechanical properties of crushed material and kinematics of the working mechanism. When developing a mathematical model, the method of closed vector polygons by V. A. Zinoviev was used.

2016年6月1日 Mohammad F. Labanie J.s. Mohamed Ali M.S.I. Shaik Da This stone focuses on finding the optimal location for a piezoelectric patch for minimizing the settling time of an excited isotropic and...

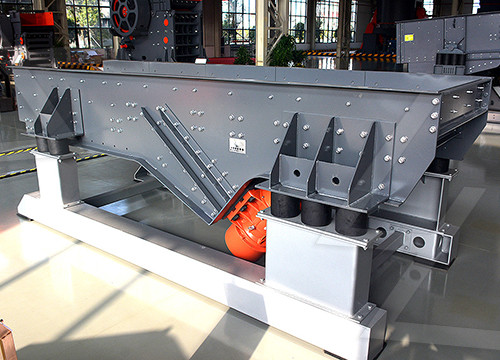

2021年1月30日 Abstract The vibrations of a vibrating jaw crusher model, excited by two self-synchronizing unbalanced-mass vibration exciters, with allowance for the interaction with the processed medium are examined. It is found that the frequency range of stable antiphase synchronization of the exciter rotation required for normal operation of the

Simplification of jaw crusher for artisanal aggregates miners Emrod Elisante Department of Chemical and Process Engineering, University of Dar es Salaam.P. O. Box 35131 Dar es Salaam, Tanzania. Email: [email protected] Article Number D5F873A5452 Vol.1 (6), pp. 102-108,September 2009 https://doi/10.5897/JETR. Accepted: 30 June

1:59 A Jaw Crusher uses compressive force for breaking material. This mechanical pressure is achieved by the crusher's two jaws dies, one of which is stationary and the other is movable. These two vertical manganese jaw dies create a V-shaped cavity called the crushing chamber, where the top of the crushing chamber is larger than the bottom.

2021年2月1日 Simple maintenance Jaw-faces are retained by a mechanical wedge locking system removing the need to access bolts behind the cast front end frame of the crusher. Replaceable backing plates protect the jaw die seating areas on the front end Long life, low maintenance and reduced operating cost

2019年5月31日 Compound Pendulum Jaw Crusher Structure Design Simplification. 2012/9/17 18:37:58 As is known to all that the compound pendulum jaw crusher can be simplified as the crank slotted link mechanism. The connecting rod is the simplified version of the movable jaw. The points on the connecting rod correspond to those on the

2022年9月20日 The plate dimensions of the un-optimised jaw crusher were modelled using ANSYS Design Modeller 2021, as shown in Fig. 3.The load and boundary conditions for the static structural analysis were as shown in Fig. 4.Design of Experiments (DoE) was then conducted where the minimum and maximum values of the target parameters were

2017年6月30日 Moreover, the wear of the jaw liner profile lowers the crusher performance by affecting the shape and the overall size of the crushed particles [12, 13]. Warping and wear of the jaw plate cause a

2021年9月21日 1 Citations Metrics Abstract The fragmentation rate and particle size distribution of the muckpile after blasting have important influences on the performance of subsequent mining activities such as loading, hauling, crushing, grinding, and the overall costs of the mine.

2016年1月1日 Introduction The first stage of size reduction of hard and large lumps of run-of-mine (ROM) ore is to crush and reduce their size. Softer ores, such as placer deposits of tin, gold, mineral sands, etc., do not require such a treatment.

2021年1月30日 Abstract The vibrations of a vibrating jaw crusher model, excited by two self-synchronizing unbalanced-mass vibration exciters, with allowance for the interaction with the processed medium are examined. It is found that the frequency range of stable antiphase synchronization of the exciter rotation required for normal operation of the

2021年2月1日 Simple maintenance Jaw-faces are retained by a mechanical wedge locking system removing the need to access bolts behind the cast front end frame of the crusher. Replaceable backing plates protect the jaw die seating areas on the front end Long life, low maintenance and reduced operating cost

1:59 A Jaw Crusher uses compressive force for breaking material. This mechanical pressure is achieved by the crusher's two jaws dies, one of which is stationary and the other is movable. These two vertical manganese jaw dies create a V-shaped cavity called the crushing chamber, where the top of the crushing chamber is larger than the bottom.

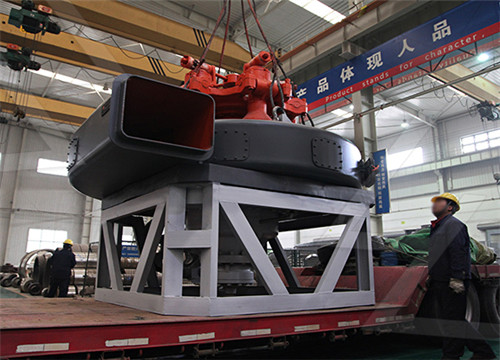

2023年6月23日 The Finlay® LJ-130 hybrid mobile jaw crusher is the largest mobile jaw crusher in our range and has been developed for large-scale quarry and mining operations.The plant’s electrically driven power systems provide significant cost advantages and environmental efficiencies.

Simplification of Jaw crusher for Artisanal Academic Journals. EN. English Deutsch Français Español Português Italiano Român Nederlands Latina Dansk Svenska Norsk Magyar Bahasa Indonesia Türkçe Suomi Latvian Lithuanian česk

2019年5月31日 Compound Pendulum Jaw Crusher Structure Design Simplification. 2012/9/17 18:37:58 As is known to all that the compound pendulum jaw crusher can be simplified as the crank slotted link mechanism. The connecting rod is the simplified version of the movable jaw. The points on the connecting rod correspond to those on the

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين